Local PPE makers decry gov’t ‘preference' for traders, importers

MANILA, Philippines — Filipino producers of personal protective equipment this week aired their concern over the government's procurement process which they claim favors traders and importers and results in the "dumping of substandard PPE" in the country.

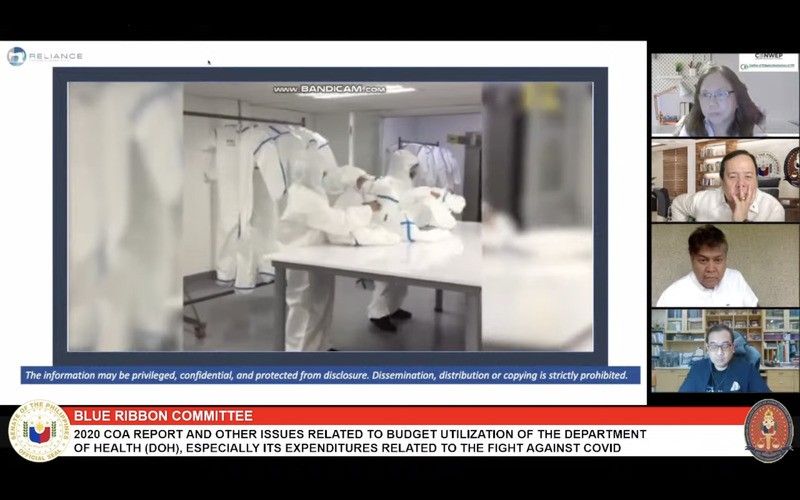

Members of the Coalition of Philippine Manufacturers of PPE and the Confederation of Wearables Exporters of the Philippines said this in a joint statement delivered before the Senate Blue Ribbon Committee on Thursday as the latter resumed its probe on reported deficiencies in pandemic spending.

CPMP executive director Rosette Carillo told senators that member firms of CPMP answered the Department of Trade and Industry's call last year to repurpose their factories for the production of PPE but "encountered many of the problems that have been the subject of [the Senate] committee's investigation."

"Most CPMP members have stopped manufacturing PPE" since then, according to Carillo, largely due to issues with the Department of Budget and Management's procurement process, including "loopholes" in its standards and testing of products which rendered them "no match to traders that merely repack expired PPE."

"Every time substandard PPE made by a foreign worker is dumped here, a Filipino worker is always marginalized," she added. "The issue of dumping worsened our already bleak prospects during the pandemic."

The government's top pandemic supplier by far, Pharmally Pharmaceutical Corp., is a middleman between the government and other suppliers but managed to corner deals worth P10.4 billion as of September 2021.

READ: ‘Shortcut’: Senators call out incomplete, anomalous Pharmally procurement papers

PS-DBM standards and testing questioned

Local makers scored the PS-DBM's procurement process for placing "no emphasis on the importance of PPE as a medical device, or the need to pass international standards for testing PPE, or the validation of certifications on the testing."

"PS-DBM merely states that PPE masks should be 'surgical, disposable, earloop, 3- ply, wired.' The masks are not even expected to have a Certificate of Product Registration from the Food and Drug Administration (FDA)," Carillo said.

She explained that the lack of standards and testing for masks and other PPE items means that CPMP's member firms, which adhere to international standards as exporters, lose out to traders who repackage "expired" PPE.

"The whole point [of] wearing masks is to protect a person from COVID-19. Merely having masks that are 'surgical, disposable, earloop, 3-ply, wired' will not do that."

The local firms also flagged PS-DBM's "unclear" criteria for PPE coveralls, which include conformity to "ASTM FI671 standard or equivalent."

The standard is a simple testing method for measuring the effectiveness of PPE materials to resist penetration by viruses in bodily fluids during continuous liquid contact with an EU testing method equivalent called EN14126.

"Without specifying what other standards may be considered an 'equivalent,' the term becomes open to interpretation. For CPMP whose PPE conforms to the gold standard of ASTM F1671, this loophole is extremely unfair," Carillo said.

"But for Filipino healthcare workers, this loophole can be fatal."

'Favored firms dumping substandard, foreign-made PPE on the Philippines'

Issues with the PS-DBM's standards and testing, local makers said, result in "the dumping of substandard PPE from foreign sources."

"CPMP and other local exporters are unprotected from importers whose predatory pricing endangers healthcare workers as well as the Philippine economy."

PS-DBM's procurement process overall favors traders and importers too, according to the local firms, who cited the agency's demand for "short term deliveries for high volume, high-value orders of PPE."

"To our members, this was a disadvantage because before they could even begin manufacturing- their raw materials had to pass international testing standards," Carillo said. "They had to go abroad for this since there is no FDA- accredited testing facility here."

"They also submitted the finished product for testing. This two-tiered process would add four weeks to their production cycle. Meanwhile, traders/importers did not have to bother with any of this."

Among CPMP's members is EMS Components Assembly, a local firm that repurposed its factory to shift to mask production only to have its shipments repeatedly delayed by PS-DBM which initially awarded it a P1.3 billion contract.

When they were finally allowed to ship the remaining 75% of PS-DBM's order, they were asked to cut down their unit price to match the market, reducing their total sales to P523 million, less than half of the original contract. He told senators the firm ended up losing instead of making money from the deal.

Other members of CPMP include Reliance Producers Cooperative (Reliance) in Carmona, Cavite which is 100% Filipino-owned, and Medtecs International Corporation Ltd. in the Bataan Freeport Area which is 40% owned by Citibank Nominees Singapore Pte. Ltd.

Legislative solution sought

Member firms of CPMP and CONWEP also expressed their support for Senate Bill No. 1766 or the proposed Pandemic Protection Act which they said would address many of their concerns.

The bill was introduced by Senate President Pro Tempore Ralph Recto in August 2020 and is pending at the committee level with the support of co-sponsors Sens. Sonny Angara, Risa Hontiveros, Francis Pangilinan and Imee Marcos.

One of the other concerns the measure would address would be local makers' push for a stockpiling program for PPEs. They said the existence of such a program will allow the country to respond quickly in the event of another public emergency.

"That will allow our emerging PPE sector to gain [a] foothold," Carillo said. "That will allow us to bring back the jobs that were lost during the pandemic, and even generate more."

She said local makers were ready to invest some USD35 million to produce medical-grade PPEs to grow a PPE sector at par with global producers.

"But none of these would actually matter if government does not improve its procurement processes, does not collaborate with the emerging PPE sector on planning the production, supply and delivery of the country’s yearly and stockpiling requirements for PPE."

"With the proposed Pandemic Protection Act, however, we find cause to be optimistic about the future of our emerging PPE sector," Carillo added. "Because the proposed law’s key policies on 'Buy Filipino,' stockpiling, long- term sustainability of local production of medical-grade PPE, they ensure National Health Security."

- Latest

- Trending